As human beings we act and prepare based on accurate future predictions since it is inherently our nature to seek certainty. Consequently, our planning endeavors often revolve around refining demand planning and forecasting for precise foresight. However, despite investing substantial time and effort in predicting a specific forecast, there is still a lot of ambiguity. o.

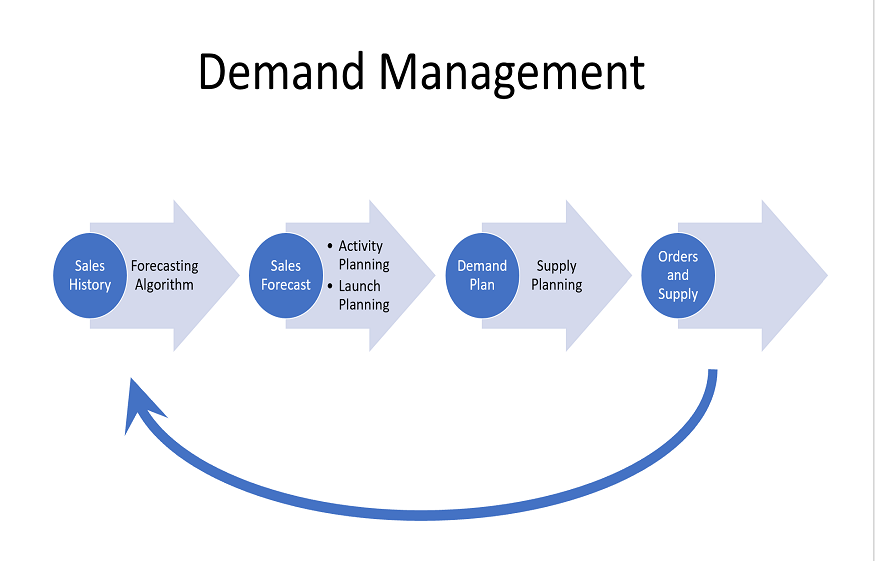

Supply chain leaders frequently prioritize forecast accuracy, considering it a critical concern amid the heightened demand fluctuations of contemporary markets. They rely on projected demand to strategize and make informed decisions. Nonetheless, they face limitations in altering forecasts beyond their inherent variability. Their capacity lies in responding to this variability through supply chain adjustments.

In the distribution sector, the gap between producers and consumers acts as a limiting factor for the supply chain. This industry faces challenges such as escalating competitive pressures, expanding SKU (Stock Keeping Unit) varieties, and the surging influence of e-commerce. Moreover, distributors now grapple with mounting uncertainties regarding supplier lead times and product availability.

As demand surges and workforce shortages further stress distributors, the prevalent supply chain challenges create an opportunity for enterprises to outperform their rivals.

How do Uncertainties Affect Businesses?

Demand volatility is tied to two apprehensions: overestimation and underestimation of demand. Overestimating leads to reduced return on assets (ROA) as resources are squandered on unnecessary acquisitions, anticipating a surplus demand that fails to manifest. On the other hand, underestimation results in diminished customer satisfaction, escalated production costs, and compromised quality.

These risks reverberate across the organization, influencing aspects like investor relations, supplier growth, new product creation, product/process engineering, supplier evaluation, and customer service. To navigate these challenges, businesses must adopt a cross-functional approach to demand planning and forecasting.

Data Analytics to Manage Uncertainty

Just five or six years ago, businesses faced challenges in obtaining comprehensive data for seamlessly integrating analytical models into their forecasting processes and efficiently analyzing this data. Historically, their focus was largely internal, centered on marketing and supply chain data like distributor estimates, sales projections, product lead times, inventory levels, production capacity, and workforce size.

Today, the public domain is witnessing an explosion in openly accessible information, fueled by the growth of “big data” and improved methods of accessing it. This shift allows businesses to tap into macroeconomic data that is not only more accurate but also predictive compared to previous options. This extends to customer, product, and competitor information. By combining this economic data with their own proprietary information, businesses are forging a new proactive approach to mitigating the risks associated with demand planning and forecasting.

Enhancements are being made to the planning and forecasting procedures. Various business units involved in the company’s planning procedures are now benefiting from significantly enhanced accuracy in information, courtesy of pioneering adopters of this novel approach who are leveraging data-driven analytical instruments. With improved information and a cohesive cross-functional outlook, the challenges posed by fluctuations in demand can be mitigated more effectively.

AI-powered Demand Planning and Forecasting Reducing the Effect of Turbulent Situations

Improving planning efforts empowers distributors to minimize the likelihood of future supply disruptions, enabling them to maintain service levels even when faced with supply limitations. The subsequent strategies can support planners in achieving success within the evolving operational environment.

Accurate Forecasting of Uncertain Demand

Gaining a comprehensive understanding of demand serves as the initial stride towards optimizing service levels amidst the unpredictability of the supply chain. Modern tools for demand planning and forecastingdelve into the intricate factors influencing demand. Employing advanced algorithms to scrutinize diverse demand variables, probabilistic planning then generates a spectrum of potential outcomes, assigning probabilities to values within the range. This planning approach incorporates not only the projected demand figure but also the likelihood of demand occurring in specific periods.

The subsequent phase entails the exploration of prevailing patterns and behaviors through short-term demand planning and forecasting and demand sensing. Planners can employ AI-driven projections to monitor triggers in demand, aiding decisions on whether to scale back or amplify demand volumes. Leveraging contemporary planning solutions, planners can gain clearer insights into shifts in demand by tracing their correlation with external factors.

Right-Sizing Inventory

Enhancing demand planning and forecasting and adopting a well-informed inventory strategy is crucial to avoid both shortages and excesses. Employing safety stock serves as a safeguard against uncertainties. To assess the impact of diverse supply parameters—such as extended lead times, modified supplier restrictions, and varied ordering frequencies—on inventory goals, planners can engage in hypothetical scenarios. This scenario-based approach offers a valuable understanding of the inventory expenses linked with different service-level objectives. For instance, it elucidates the cost of additional inventory required to elevate the service level of a specific product from 96% to 98%.

Better Visibility of Supply Requirements

Enhanced supply chain management empowers planners to swiftly access scarce inbound resources from vendors. The assurance of reliability grows stronger when supply needs spanning a more extensive time frame come into view, enabling both extended-term strategic planning and immediate tactical choices. By amalgamating the current plan with a contemporary demand planning and forecasting solution, future inventory projections become apparent. This forecasting solution can further be integrated with a supplier calendar to amplify visibility even more.

About the Company

Fountain9 supports enterprises in achieving precise demand forecasts that encompass all potential risks and uncertainties, utilizing their AI-powered demand planning software known as Kronoscope. This software factors in 9 distinct elements to ensure the delivery of accurate forecast analyses. This approach empowers businesses to minimize surplus inventory and uphold an ideal stock level for effectively fulfilling demand.